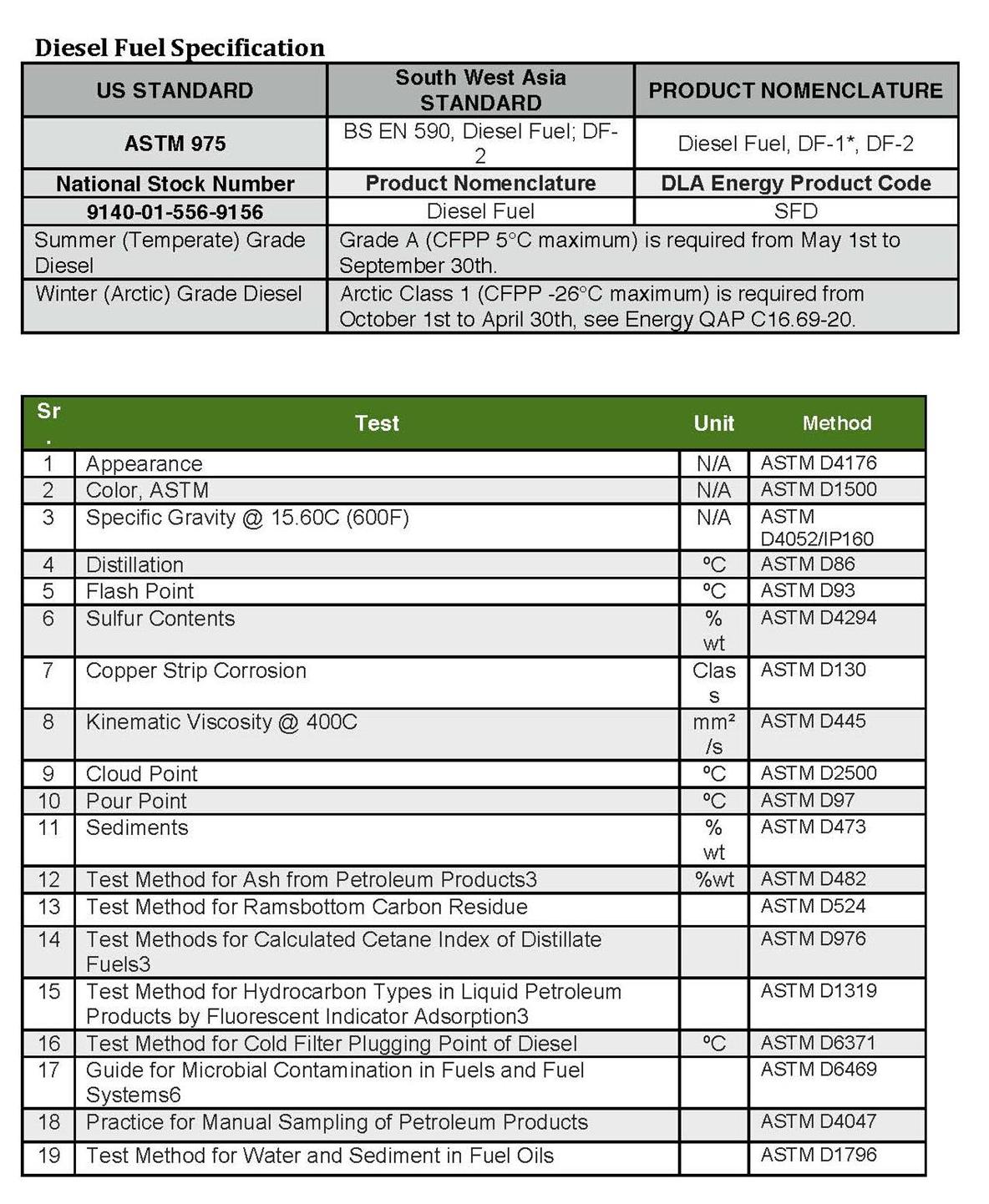

Diesel (ASTM D975)Diesel fuel consists of a mixture of cracked and straight-run stocks. This produces a fuel of good handling characteristics and availability. Continued innovations in engine and vehicle design and increasing engine performance requirements impose greater emphasis on fuel stability and cleanliness. In addition, the relatively low turnover rates of diesel fuel in non-tactical situations require a fuel that resists deterioration over time.Diesel fuel may contain up to 5 volume percent biodiesel.

Water and Sediment Control

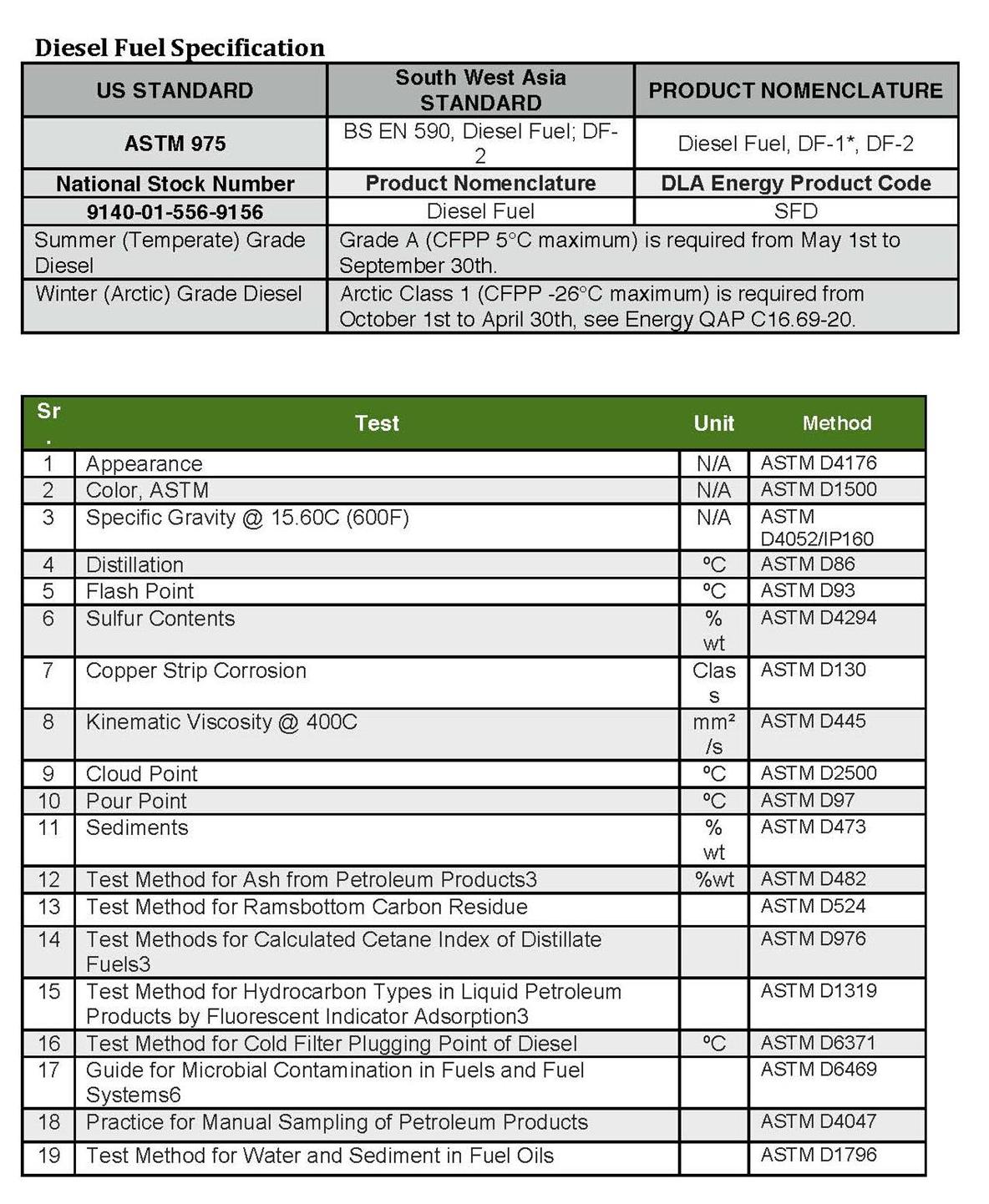

Diesel fuel shall be delivered to consuming vehicles through filters or filter separators in order to keep water and/or sediment contamination to the absolute minimum while preventing corrosion and wear of fuel pumps and injectors. Whether a filter or a filter separatoris required, it will be based on the operational requirements at the specific location. For ASTM D975 diesel fuel, Test Method ASTM D2709 is used for Grades No.1-D, and No. 2-D (all sulfur levels) and Test Method ASTM D1796 is used for Grade No.4-D.

Quality Fuel DeliveriesIt shall be reemphasized that personnel responsible for delivery of fuel shall take all steps necessary to ensure fuel delivered to customer is clean, bright, on-specification and water-free. Samples may be taken and inspected visually as frequently as necessary. If specification or intra-Governmental receipt limits are exceeded, it is obvious that improvement in fuel handling is urgently required. Identifying the source of contamination to prevent future occurrences is the most important aspect of determining necessary corrective action. While changing filter-separator elements may appear to resolve the problem, this action provides only temporary relief if excessive solids or water exists upstream of the filter-separator. Existing and potential problem areas shall be promptly identified and brought to the attention of responsible personnel.

Fuel Quality and Fuel Contamination

The main causes of fuel contamination are commingling with other petroleum products and contamination with water; solids and microbiological growth.

This specification covers seven grades of diesel fuel under two main grades of Diesel Fuel DF-1 and DF-2. Diesel fuel has been hydrocarbon molecules refined from petroleum. As a result, Specification D975 has evolved to define performance requirements (and tests to determine if those requirements were met) for diesel (compression ignition) engine fuels composed of conventional hydrocarbon oils refined from petroleum.

Cetane Number

Cetane number is a measure of the ignition quality of the fuel and influences combustion roughness. Accordingly, the cetane number specified should be as low as possible to assure maximum fuel availability.

Distillation

The fuel volatility requirements depend on engine design. Best fuel economy is generally obtained from the heavier types of fuels.

Viscosity

Maximum viscosity, on the other hand, is limited by considerations involved in engine design and size, and the characteristics of the injection system.

Carbon Residue

Carbon residue gives a measure of the carbon depositing tendencies of a fuel oil when heated in a bulb under prescribed conditions.

Sulfur

This is one of the important content in Diesel, lesser the sulfur content, better the Diesel quality. The effect of sulfur content on engine wears and deposits appears to vary considerably in importance and depends largely on operating conditions.

Flash Point

The flash point is importance in connection with legal requirements and safety precautions involved in fuel handling and storage.

Cloud Point

Cloud point is of importance in that it defines the temperature at which a cloud or haze of wax crystals appears in the oil under prescribed test conditions which generally relates to the temperature at which wax crystals begin to precipitate from the oil in use.

Hot Shot’s Diesel Winter Anti-Gel Properties

We have selected Hot Shot’s Diesel Winter Anti-Gel provides ”Premium Diesel” qualities to standard diesel fuels in terms of detergency, stability, lubricity, winter operability, and cetane number. We will provide lab testing for the approval before use. Its effective anti-gel additive greatly improves cold temperature performance. In addition, Diesel Winter Anti-Gel contains a powerful cetane improver for quicker cold starts and a maximum boost in power and performance. Diesel Winter Anti-Gel is recommended for all diesel engines.

How it works

Detergency – Diesel Winter Anti-Gel reduces injector nozzle coking, as demonstrated in the Cummins L-10 125-Hour Injector Depositing Test.

Cold Temperature Performance – Diesel Winter Anti-Gel lowers Pour Point, Cold Filter Plugging Point, and Low Temperature Fluidity.

Cetane – Diesel Winter Anti-Gel improves ignition efficiency, improves cold starts, reduces warm up time, smooths engine operation, increases power and fuel economy.

Stability – Fuel can also be treated with Diesel Winter Anti-Gel to pass the ASTM D-6468 Thermal Stability Test as well as the other commonly used storage stability tests.

Lubricity – Diesel Winter Anti-Gel improves lubricity of diesel fuels in both the BOCLE Test and the HFRR Test, which is a critical factor with low-sulfur No. 2 and especially with kerosene blended fuels.

Rust and Corrosion Protection – Prevents all types of rust and corrosion in fuel lines, strainers, pumps and injectors.

This specification covers seven grades of diesel fuel under two main grades of Diesel Fuel DF-1 and DF-2. Diesel fuel has been hydrocarbon molecules refined from petroleum. As a result, Specification D975 has evolved to define performance requirements (and tests to determine if those requirements were met) for diesel (compression ignition) engine fuels composed of conventional hydrocarbon oils refined from petroleum.

Cetane Number

Cetane number is a measure of the ignition quality of the fuel and influences combustion roughness. Accordingly, the cetane number specified should be as low as possible to assure maximum fuel availability.

Distillation

The fuel volatility requirements depend on engine design. Best fuel economy is generally obtained from the heavier types of fuels.

Viscosity

Maximum viscosity, on the other hand, is limited by considerations involved in engine design and size, and the characteristics of the injection system.

Carbon Residue

Carbon residue gives a measure of the carbon depositing tendencies of a fuel oil when heated in a bulb under prescribed conditions.

Sulfur

This is one of the important content in Diesel, lesser the sulfur content, better the Diesel quality. The effect of sulfur content on engine wears and deposits appears to vary considerably in importance and depends largely on operating conditions.

Flash Point

The flash point is importance in connection with legal requirements and safety precautions involved in fuel handling and storage.

Cloud Point

Cloud point is of importance in that it defines the temperature at which a cloud or haze of wax crystals appears in the oil under prescribed test conditions which generally relates to the temperature at which wax crystals begin to precipitate from the oil in use.

Hot Shot’s Diesel Winter Anti-Gel Properties

We have selected Hot Shot’s Diesel Winter Anti-Gel provides ”Premium Diesel” qualities to standard diesel fuels in terms of detergency, stability, lubricity, winter operability, and cetane number. We will provide lab testing for the approval before use. Its effective anti-gel additive greatly improves cold temperature performance. In addition, Diesel Winter Anti-Gel contains a powerful cetane improver for quicker cold starts and a maximum boost in power and performance. Diesel Winter Anti-Gel is recommended for all diesel engines.

How it works

Detergency – Diesel Winter Anti-Gel reduces injector nozzle coking, as demonstrated in the Cummins L-10 125-Hour Injector Depositing Test.

Cold Temperature Performance – Diesel Winter Anti-Gel lowers Pour Point, Cold Filter Plugging Point, and Low Temperature Fluidity.

Cetane – Diesel Winter Anti-Gel improves ignition efficiency, improves cold starts, reduces warm up time, smooths engine operation, increases power and fuel economy.

Stability – Fuel can also be treated with Diesel Winter Anti-Gel to pass the ASTM D-6468 Thermal Stability Test as well as the other commonly used storage stability tests.

Lubricity – Diesel Winter Anti-Gel improves lubricity of diesel fuels in both the BOCLE Test and the HFRR Test, which is a critical factor with low-sulfur No. 2 and especially with kerosene blended fuels.

Rust and Corrosion Protection – Prevents all types of rust and corrosion in fuel lines, strainers, pumps and injectors.

This specification covers seven grades of diesel fuel under two main grades of Diesel Fuel DF-1 and DF-2. Diesel fuel has been hydrocarbon molecules refined from petroleum. As a result, Specification D975 has evolved to define performance requirements (and tests to determine if those requirements were met) for diesel (compression ignition) engine fuels composed of conventional hydrocarbon oils refined from petroleum.

Cetane Number

Cetane number is a measure of the ignition quality of the fuel and influences combustion roughness. Accordingly, the cetane number specified should be as low as possible to assure maximum fuel availability.

Distillation

The fuel volatility requirements depend on engine design. Best fuel economy is generally obtained from the heavier types of fuels.

Viscosity

Maximum viscosity, on the other hand, is limited by considerations involved in engine design and size, and the characteristics of the injection system.

Carbon Residue

Carbon residue gives a measure of the carbon depositing tendencies of a fuel oil when heated in a bulb under prescribed conditions.

Sulfur

This is one of the important content in Diesel, lesser the sulfur content, better the Diesel quality. The effect of sulfur content on engine wears and deposits appears to vary considerably in importance and depends largely on operating conditions.

Flash Point

The flash point is importance in connection with legal requirements and safety precautions involved in fuel handling and storage.

Cloud Point

Cloud point is of importance in that it defines the temperature at which a cloud or haze of wax crystals appears in the oil under prescribed test conditions which generally relates to the temperature at which wax crystals begin to precipitate from the oil in use.

Hot Shot’s Diesel Winter Anti-Gel Properties

We have selected Hot Shot’s Diesel Winter Anti-Gel provides ”Premium Diesel” qualities to standard diesel fuels in terms of detergency, stability, lubricity, winter operability, and cetane number. We will provide lab testing for the approval before use. Its effective anti-gel additive greatly improves cold temperature performance. In addition, Diesel Winter Anti-Gel contains a powerful cetane improver for quicker cold starts and a maximum boost in power and performance. Diesel Winter Anti-Gel is recommended for all diesel engines.

How it works

Detergency – Diesel Winter Anti-Gel reduces injector nozzle coking, as demonstrated in the Cummins L-10 125-Hour Injector Depositing Test.

Cold Temperature Performance – Diesel Winter Anti-Gel lowers Pour Point, Cold Filter Plugging Point, and Low Temperature Fluidity.

Cetane – Diesel Winter Anti-Gel improves ignition efficiency, improves cold starts, reduces warm up time, smooths engine operation, increases power and fuel economy.

Stability – Fuel can also be treated with Diesel Winter Anti-Gel to pass the ASTM D-6468 Thermal Stability Test as well as the other commonly used storage stability tests.

Lubricity – Diesel Winter Anti-Gel improves lubricity of diesel fuels in both the BOCLE Test and the HFRR Test, which is a critical factor with low-sulfur No. 2 and especially with kerosene blended fuels.

Rust and Corrosion Protection – Prevents all types of rust and corrosion in fuel lines, strainers, pumps and injectors.

This specification covers seven grades of diesel fuel under two main grades of Diesel Fuel DF-1 and DF-2. Diesel fuel has been hydrocarbon molecules refined from petroleum. As a result, Specification D975 has evolved to define performance requirements (and tests to determine if those requirements were met) for diesel (compression ignition) engine fuels composed of conventional hydrocarbon oils refined from petroleum.

Cetane Number

Cetane number is a measure of the ignition quality of the fuel and influences combustion roughness. Accordingly, the cetane number specified should be as low as possible to assure maximum fuel availability.

Distillation

The fuel volatility requirements depend on engine design. Best fuel economy is generally obtained from the heavier types of fuels.

Viscosity

Maximum viscosity, on the other hand, is limited by considerations involved in engine design and size, and the characteristics of the injection system.

Carbon Residue

Carbon residue gives a measure of the carbon depositing tendencies of a fuel oil when heated in a bulb under prescribed conditions.

Sulfur

This is one of the important content in Diesel, lesser the sulfur content, better the Diesel quality. The effect of sulfur content on engine wears and deposits appears to vary considerably in importance and depends largely on operating conditions.

Flash Point

The flash point is importance in connection with legal requirements and safety precautions involved in fuel handling and storage.

Cloud Point

Cloud point is of importance in that it defines the temperature at which a cloud or haze of wax crystals appears in the oil under prescribed test conditions which generally relates to the temperature at which wax crystals begin to precipitate from the oil in use.

Hot Shot’s Diesel Winter Anti-Gel Properties

We have selected Hot Shot’s Diesel Winter Anti-Gel provides ”Premium Diesel” qualities to standard diesel fuels in terms of detergency, stability, lubricity, winter operability, and cetane number. We will provide lab testing for the approval before use. Its effective anti-gel additive greatly improves cold temperature performance. In addition, Diesel Winter Anti-Gel contains a powerful cetane improver for quicker cold starts and a maximum boost in power and performance. Diesel Winter Anti-Gel is recommended for all diesel engines.

How it works

Detergency – Diesel Winter Anti-Gel reduces injector nozzle coking, as demonstrated in the Cummins L-10 125-Hour Injector Depositing Test.

Cold Temperature Performance – Diesel Winter Anti-Gel lowers Pour Point, Cold Filter Plugging Point, and Low Temperature Fluidity.

Cetane – Diesel Winter Anti-Gel improves ignition efficiency, improves cold starts, reduces warm up time, smooths engine operation, increases power and fuel economy.

Stability – Fuel can also be treated with Diesel Winter Anti-Gel to pass the ASTM D-6468 Thermal Stability Test as well as the other commonly used storage stability tests.

Lubricity – Diesel Winter Anti-Gel improves lubricity of diesel fuels in both the BOCLE Test and the HFRR Test, which is a critical factor with low-sulfur No. 2 and especially with kerosene blended fuels.

Rust and Corrosion Protection – Prevents all types of rust and corrosion in fuel lines, strainers, pumps and injectors.